Passive House in the Woods

The first certified Passive House in Wisconsin is built using "everything right” design.

The Passive House in the Woods is the first certified Passive House project in Wisconsin. Completed in 2010, it delivers monitored net-zero performance for all energy consumed on site in this cold western Wisconsin climate zone.

The home features a 3-bedroom, 1,940 square foot, three-story design with a walk-out basement, as well as a rooftop terrace. Located on the outer edge of a residential development, Passive House in the Woods provides stunning views of the the St. Croix river valley, which get better the higher one climbs in the home.

Simply the Best.

“Everything Right” Design

The Passive House in the Woods is a certified Passive House. It actually outperforms the most stringent building energy standard in the world in a few key aspects.

It was designed from the ground up to perform with our Client setting clear targets for the design and build team. It was the expressed goal to design to net-zero energy with access to “only” just under 5kWp of solar panels and one hot water solar preheater panels.

In addition to the performance, we also paid a lot of attention to details—both outside and inside. Maximizing endurance and minimizing maintenance, we made use of resilient insulated concrete form construction in conjunction with certified wood framing, and steel structure where it counts.

Stormwater is meticulously managed on site to divert water away from the building and making it useful on site with the help of rain gardens. Parts of the site were restored using only native plantings, while other sections are dedicated to permaculture and organic food production.

The Earth- and people-friendly palette we co-developed with expert interior designers at InUnison was dubbed “warm modern”. It responds to the Client’s priorities for natural, healthy materials that age gracefully. His love of the outdoors and nature were the inspiration for the use of uncured earthen plaster, milk-paint and wood harvested on site.

Passive House

The building envelope, which consists of exterior walls, windows, doors, basement slab, and the roof was designed according to Passive House principles to radically reduce the amount of energy used to condition the building.

The exterior wall assembly of the Passive House in the Woods consists of 11” thick Insulated Concrete Forms (ICF) for structure, and an additional 11” thick Exterior Insulation and Finish System (EIFS) facade with an overall R-value of 70—about 3.5 times the code-required amount.

Windows and exterior doors are Passive House certified, come with a very high solar heat gain coefficient (64%), triple pane low-E coated glazing, as well as insulated frames for installed R-values of 8.

The basement slab rests on 12” of extruded polystyrene insulation with an R-value of 60.

The low-sloped roof utilizes an average of 14” of polyisocyanurate insulation with an R-value of 95, which compares to the code-required R-38.

These highly insulating assemblies are commonly referred to as super-insulation. Performance is further enhanced by the fact that the home is extremely airtight, measuring only 64 CFM air leakage at 50 Pascals pressure, or 0.25 ACH50. This make Passive House in the Woods one of the tightest buildings in North America.

Walkout Basement Plan

First Floor Plan

Second Floor Plan

Rooftop Plan

Heat-Recovery Ventilation

The mechanical system in a Passive House is typically centered around a heat-recovery ventilation system. In milder climates, this system provides all the necessary heating energy, as well as outside air needed for balanced, hygienic ventilation, and therefore superb indoor air quality.

The heat-recovery ventilation system in the Passive House in the Woods consists of a high efficiency heat-recovery ventilator, a home-run tube distribution system, as well as a ground-source heat exchanger that connects to a 600 foot-long PEX-tube, which is buried well below frost on the property. This “earthloop” pre-heats and pre-cools/ dehumidifies the fresh air supply to the home and therefore becomes a “passive” air conditioner.

No Boiler, No Furnace

In extremely cold climates, the Passive House paradigm of heating the fresh air supply changes slightly. While the overall annual energy goals for a Passive House can easily be met, the extremely cold peak winter temperatures call for a small additional heat source.

At the Passive House in the Woods, electric in-floor heating mats with local room-air thermostats were installed to provide the 3 kW or 10 kBtu required for the job. That compares to the energy draw of two hair-dryers to heat the entire home on the coldest day of the year. There is not a boiler, or furnace in this house.

Two split-ducted air-to-air heat pumps can be used for summer cooling, as well as winter heating as desired.

Renewable Energy Systems

Renewable energy systems are optional and not required by the Passive House standard. Our client chose to achieve a net-zero energy balance with the help of a 4.7kWp photovoltaic system.

The domestic hot water system utilizes a 40 square foot hot water solar collector on the roof to pre-warm water in a 50 gallon storage tank. It is capable of providing over 85% of the hot water used in the home. Backup water heating is provided by a small electric on-demand water heater.

Certifications and Highlights

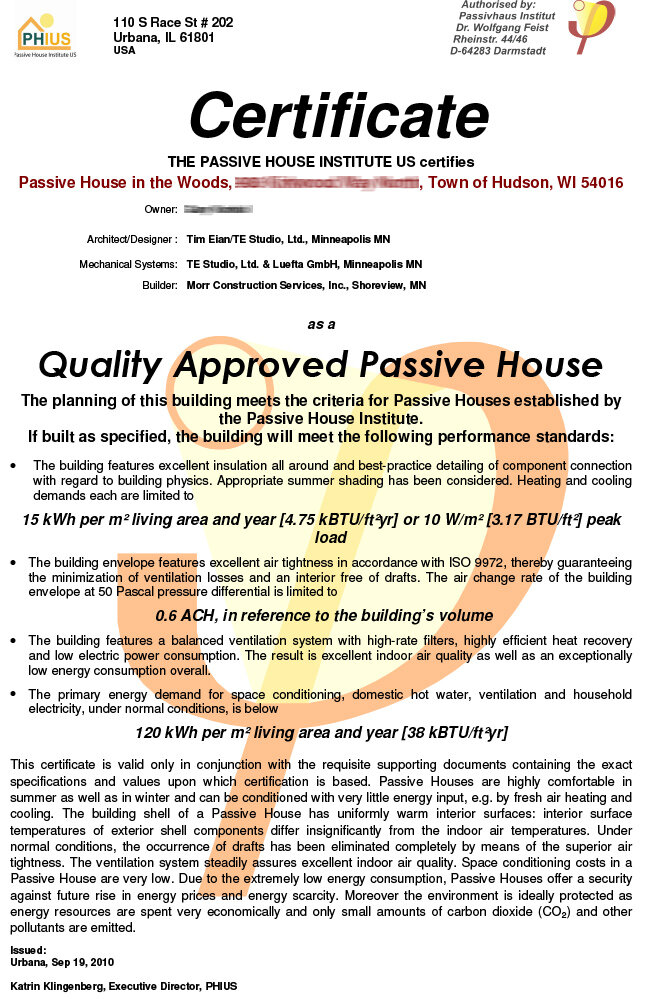

Certified Passive House - Project ID 1770 (first certified Passive House in Wisconsin)

PHIUS+ certified - Project ID 1039

GreenStar Gold (certified New Home)

HERS: 5+ Star Home (highest category)

Energy Star Version 2 Qualified Home

2011 Green Builder Magazine Technical Achievement of the Year Award

Published in multiple books and magazines

Super-insulated, airtight building envelope (0.25 ACH50)

Passive House windows with triple-pane glazing and exterior motorized shading

Thermal bridge-free detailing and construction

Whole-house, balanced, heat-recovery ventilation system with ground-source heat exchanger

Electric cold-climate air-to-air heat pump system for heating and cooling with electric in-floor mat backup

Solar-thermal hot water system with wastewater heat recovery and continuously insulated pipes

LED lighting throughout

4.75 kWp photovoltaic system on roof and articulating ground mount; grid tied

Level-2 vehicle charging in attached garage

Accessible main floor design and visitability, zero-step entries

Durable earth and people friendly and reclaimed materials throughout

Sustainable landscaping and extensive stormwater management with rain gardens

Project Team

Type: Small, free-standing single family home

Location: Town of Hudson Wisconsin, suburban/ rural

Construction: New construction, mixed ICF, wood and steel

Design: TE Studio

Interior: InUnison Design

Landscape: Laurie McRostie Landscape Architect

Lighting: Carol Chaffee and Associates

Mechanical: TE Studio & Lüfta

Structural: Mattson MacDonald Young

Renewable Energy: Energy Concepts

Building Science: Built Environments

Builder: Morr Construction

Project: 2008 – 2010

Photo Credits:

Chad Holder, Chad Holder Photography

Corey Gaffer, Gaffer Photography

TE Studio